Invisible Wood Joints. Bring parts together with dowels and glue. Uses: This type of wood joint is often used in furniture making and crafts.

The process strips wood of all its color. We aren't always able to employ distraction, but when done properly it can indeed be a magical thing. The most widely known "invisible" wood joint is the dowelled joint using dowel pins.

A butt joint covered with layers of glass just won't be invisible. George Vondriska teaches you about the benefits. An organic substance named lignin is removed chemically.

Next, remove the cutter and rout the wooden joints along the left-hand edge in a clockwise direction. On one piece, spread glue within the holes, insert the dowels, and clamp it to a flat surface. The scarph joint is probably the easiest thing you'll do in the building process.

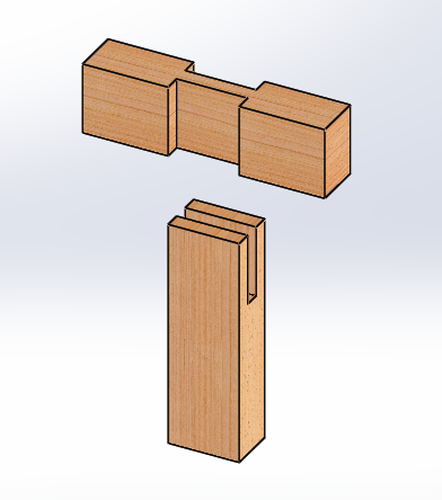

The dowel pins can be used to create corner, T-butt and edge-to-edge joints.

Woodworking bow tie joint woodworking projects. Joining a Top Plank to a Side Plank. Even if an item says "sold out" contact us by pressing the messenger button and we will give you an accurate time frame of.

Woodworking glue machine cut joint woodworking archive. Machinecut mortises machine cut joint woodworking archive. Woodworking: pick a pocket joint stonehaven life.

These are particu-larly popular because all that is needed to make them, is a power drill and the right wood drill bit. Doweling is another old-school joinery method, whereby two or more round sticks of wood, known as dowels, are inserted into corresponding holes in two adjoining boards to hold them together. Drill matching holes across the joint area with the help of a jig; bring parts together with dowels and glue; clamp the joint tight.

Besides, the scarph joint is much quicker than the glassed over butt joint,and easily as strong. These need to be routed accurately and precisely in order to guarantee a perfect fit. The process strips wood of all its color.

Dovetail joints are very strong and resist pulling apart through the use of wedge-shaped interlocking pieces (the wedges resemble a dove's tail). These need to be routed accurately and precisely in order to guarantee a perfect fit. Even if an item says "sold out" contact us by pressing the messenger button and we will give you an accurate time frame of.

Bring parts together with dowels and glue.

Carpenters and craftsmen of ancient China and Egypt helped perfect joinery methods that contractors and woodworkers still use today. You'll need a scrap piece of the wood you want to repair. The result: Invisible beam joints, routed and.

After routing the wooden joints, the connectors are assembled using suitable screws. +. Translucent Wood Glue provided by Titebond. Rout the interior of the material. +.

Uses: This type of wood joint is often used in furniture making and crafts. They come in a Starter-Kit, with all the drills and tools you need to use the system. Next, remove the cutter and rout the wooden joints along the left-hand edge in a clockwise direction.

Invisible beam joints are often used in timber construction. Carpenters and craftsmen of ancient China and Egypt helped perfect joinery methods that contractors and woodworkers still use today. In a square ended basic butt joint, one piece of wood butts up against another, most often perpendicularly at a right angle.

The result: Invisible beam joints, routed and. Rout the interior of the material. +. This technique has gained such popularity because all that is required to make the joints is a power drill and the relevant wood drill bit.

An organic substance named lignin is removed chemically. Invisible Glue Joints: Miter Joint (werkplaatsidc): In this instructable we will show you how to make an invisible wood glue connection without using a lot of (difficult) materials. Translucent Wood Glue provided by Titebond.

Two different wood pieces simply sit side by side, with the butt of one workpiece adjacent to the butt of another workpiece. Woodworkers form this joint by forming a recess into the edge of the timber. They come in a Starter-Kit, with all the drills and tools you need to use the system.

Two different wood pieces simply sit side by side, with the butt of one workpiece adjacent to the butt of another workpiece.

To create invisible beam joints, a combination of a router and multi-routing template is particularly practical.

Invisible Glue Joints: Miter Joint (werkplaatsidc): In this instructable we will show you how to make an invisible wood glue connection without using a lot of (difficult) materials. Dovetail joints are very strong and resist pulling apart through the use of wedge-shaped interlocking pieces (the wedges resemble a dove's tail). An organic substance named lignin is removed chemically.

In a square ended basic butt joint, one piece of wood butts up against another, most often perpendicularly at a right angle. The secrets to making invisible panel joints. Dovetail joints are very strong and resist pulling apart through the use of wedge-shaped interlocking pieces (the wedges resemble a dove's tail).

Besides, the scarph joint is much quicker than the glassed over butt joint,and easily as strong. Even if an item says "sold out" contact us by pressing the messenger button and we will give you an accurate time frame of. Two ways to obtain perfect invisible joints when edgebanding State-of-the-art customers want state-of-the-art solutions: invisible joints We have compiled the most important information on invisible joint technology in edgebanders and try to answer the key questions about this new technology.

Woodworking bow tie joint woodworking projects. Woodworkers form this joint by forming a recess into the edge of the timber. Two ways to obtain perfect invisible joints when edgebanding State-of-the-art customers want state-of-the-art solutions: invisible joints We have compiled the most important information on invisible joint technology in edgebanders and try to answer the key questions about this new technology.